Everyone has dreams.

- outlaws4x4

- May 5, 2018

- 3 min read

I have a dream of owning and racing a Trophy Truck. Now i know i kind of already had one but if we are being totally honest the 875 truck was far from a trophy truck. More like a 4wd with custom suspension and heaps of roll cage and tube to make it look cool!

When i say i want to own a Trophy Truck i mean, Custom built Chromolly and billet alloy, Long travel suspension A-Arms, Huge long travel Trailing arms to take only the biggest of coil over and bypass shocks. Full space tubular frame, Big tyres and a high horsepower screaming engine!

So how does one take a dream and turn it into reality???

For me I planed on getting back out on the track for 2019. That set my date, and since this was not going to be my first build i already knew i would need to do a lot of planing to achieve such a big goal. Its not until you sit down and start working through what you are trying to achieve that you realize how much work there is involved with building any kind of race vehicle from scratch. let alone a #TrophyTruck.

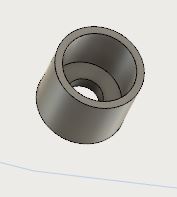

I am fortunate enough to have some highly talented and smart individuals as friends, Glen and Jnr. With their help i learnt how to use #Fusion360 which is #CAD software product which allows you to create designs and models of the project you are working on. What this meant for me was, the ability to draw and model a Trophy truck where every nut, bolt, washer, flue pump, steering wheel.... everything is drawn accurately and to original size and assembled together within the program to give you a completed model of the truck. This gives you the ability to draw brackets, panels, tabs, seat mounts, radiator mounts anything on the model and you know that if it fits it will fit in the real product.

This kind of modeling however takes a very long time, but is worth it in the long run. once you have an accurate model you can reproduce all of your parts as you need them. You can also easily make changes on the model to see if something will fit before actually making changes on the real truck.

I also purchased some other software called #Bendtech Pro This software allows you to draw tubes and then it will print out tube wraps for all the tube intersections so you can trace the perfect notch/cope onto the tube end to be cut. It also gives you bending instructions based off a straight unbent piece of tube. so you can mark up all of your bends on the straight tube before you start bending. It essentially turns your bender into a CNC bender where your arms are the stepper motors.

Once i had the frame drawn in Bendtech i imported it into #Fusion360 where i could design all of the suspension pivot points and draw them onto the model.

It is important at this stage to already know what link separation you are going to require, your wheel base measurements, your wheel track or total width along with your frame length.

In my case the frame width and length were determined by the fiberglass body i was going to be running. This is also a good point to make if your going to build something like this it is far easier to build to the body than to try and make the body fit to what you have built. so get the body first.....

Another big part of building using CAD is the ability to manufacture parts accurately. I did this by building what is known as a Jig Table #jigtable which is a table which you bolt jigs to, which hold your tubes or plates in place while they are being welded together.

This means that you now not only have to draw the part your building but you need to draw all the jigs required to hold the part in position for manufacturing.

Comments